Services and Capabilities

DeGood Dimensional Concepts offers complete manufacturing services in order to minimize effort for the customer and maximize delivery expectations. We work hand in hand with the development engineers, quality, and purchasing to deliver products with the least amount of hassle and confusion.

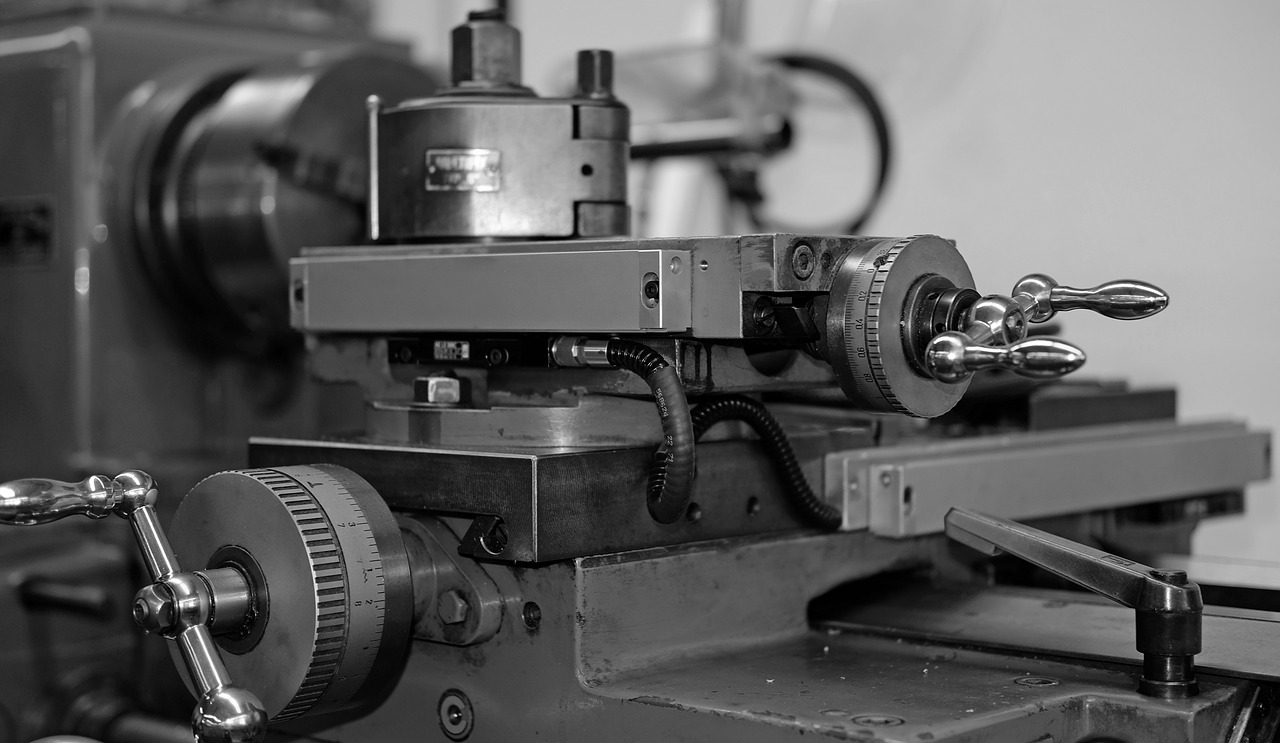

Machining

We offer full services in the following areas:

- CAD – CAM

- CNC Milling

- CNC turning

- Multi-Axis (Swiss type) turning with Thread Whirling

- Wire EDM

- Ram RDM

- Surface and thread grinding

- Centerless grinding

- Gun drilling

- Tig Welding

- Furnace brazing

- Polishing/Finishing/Coatings

- Assembly

- Heat Treating

- Labels & Packaging

Quality Control

Our quality control department is staffed with experienced medical device managers and quality control personnel. They ensure quality parts are delivered with all required documentation.

Finishing

Our metal finishing department can perform the following including, a variety of other services:

- Polishing and Buffing

- Ceramic Bead Blasting

- Various media Tumbling

- Ultrasonic Cleaning

- Laser Marking

- Electropolish

- Passivation

Multi-Axis Turning

With a great variety in Multi-axis Swiss with thread whirling capabilities and Traditional CNC turning centers, we can create cost-effective and close tolerance precision parts including:

- Plate Fixation Screws

- Multi-axial screws

- Locking devices & Spinal Rods

Multi-Axis Machining

With multiple high speed 3 and 4 Axis machining centers, we can manufacture all of the complex shapes and close tolerances required for internal and external fixation devices, including:

- Cervical Plates

- Small Bone Plates

- Fixation Devices

- Fixation Plates

- Hooks and other Spine products

- Trauma Plates, etc